TM 55-2200-001-12

Change 1

Sec. 6-Fig 65 (Rev.-11-1978)

(Drawing Redrawn 11-1978)

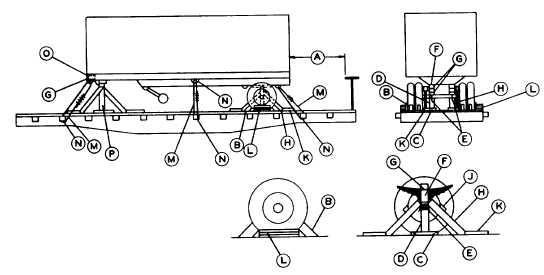

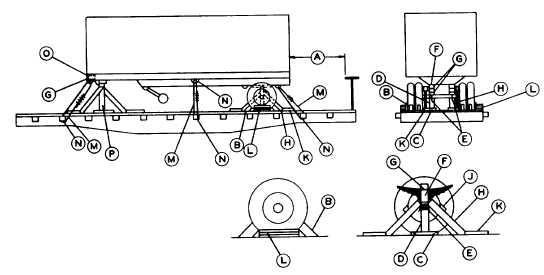

SEMI-TRAILERS-FLAT CARS

Item

No. of Pcs.

Description

A

Brake Wheel Clearance. See Fig. 2, Section No. 1.

B

2 each wheel.

Blocks, Pattern 47. Locate one against front and rear of each wheel. Secure heel of block to

floor with three 60-D nails and toe-nail side faces, where accessible, to floor with one 60-D

nail. Substitute, if desired, block pattern 16 or 17, using suitable size nails.

C

2

Axle Support Base, 2 in. x 4 in. x 16 in. lumber. Secure to Item "D" with three 30-D nails and

to floor with eight 20-D nails each.

D

2

Vertical Axle Support, 4 in. x 4 in. x 15 1/4 in. lumber, height may vary. Locate under axle.

E

2

1 in. x No. 14 B.W. Gage Hot Rolled Steel Strap. Pass around top of axle and secure each end

to side of Item "D" with two 8-D nails. CAUTION: If brake line tubing runs along top of

axle, pass the steel strap between axle and tubing so that tubing is not flattened or damaged.

F

2

Vertical Axle Block, 4 in. x 4 in. lumber, length as required. Locate over axle and under sill

of unit.

G

As required

No. 8 Gage Black Annealed Wire. Encircle Item "F" and spring housing. Use also for secure-

4 locations.

ment of Item "O" to front of trailer frame, both sides.

H

4

Diagonal Axle Blocks, 2 in. x 4 in. x 33 in. lumber. Locate against spring housing and secure

each to floor with two 20-D nails. Apply after Items "D" and "F" are secured.

J

2

Crosstie, 2 in. x 4 in. x 43 in. lumber. Locate on top of Items "H" about % the distance from

top and secure each end to Items "H" with two 20-D nails.

K

4

Cleat, 2 in. x 4 in. x 16 in. lumber. Locate against bottom of Items "H" and secure each to

floor with six 20-D nails.

L

2

Wheel Side Blocking, Block Pattern 89, Section No. 6. Use suitable protective material, such

as waterproof paper or burlap, between tire and blocking. Locate bottom portion of pro-

tective material under Item "L", top portion to extend two inches above Item "L".

E-81