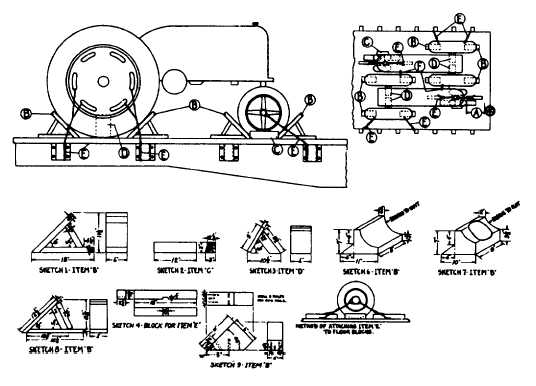

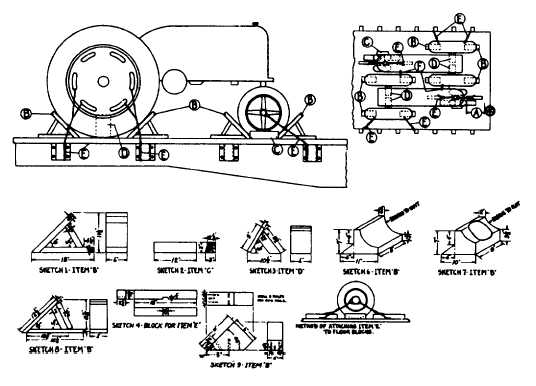

Sec. 3-Fig. 84 (Rev.-10-1968)

TRACTORS (WITH OR WITHOUT PNEUMATIC TIRES), BOTH ROW-CROP AND CONVENTIONAL,

LENGTHWISE

OR DIAGONALLY, OVER 7,000 LBS.-FLAT CARS

Item

No. of Pcs.

Description

A

Brake wheel clearance. See Fig. 2, Sec. 1.

B

Four wheel trac-

Blocks, per Sketches 1, 6, 7 or 9. Locate one against front and ear of each wheel of four-wheel

tors, 8; Row-Crop

tractors; one against front and rear of each rear wheel and against front and rear of one

tractors, 6.

front wheel of row-crop tractors. Nail each to floor with five 40-D or seven 30-D nails.

Substitute, if desired, blocks, per Sketch 8, for tractors weighing 4,000 lbs. or less, and at front wheels only for machines

weighing over 4,000 lbs. Nail each to floor with five 30-D nails.

C

1 ea. front wheel.

Blocks, per Sketch 2. Locate against outside ofwheels and nail each to floor with four 50-D nails.

D

1 ea. rear wheel.

Blocks, per Sketch 3. Locate against wheel and nail each to floor with three 30-D nails.

E

1 ea. front wheel,

Each to consist of six strands No. 9 gage black annealed wire. Pass three wires through spokes,

or ea. pr. of dual

or holes in plates, of outside front wheels, or frame, and through stake pockets; through

wheels and two

spokes, or holes in plates, of outside rear wheels, and through two stake pockets. When wires

ea. outside rear

cannot be effectively applied to stake pockets, and for units with solid disc wheels, pass

wheel.

wires over axle, or through frame of machine and underneath blocks, per Sketch 4, or tiedown plates Pattern 32. Secure

Sketch 4 blocks to floor with six 50-D nails and Pattern 32 plates with 10-D nails.

Pass three wires through spokes, or holes in plates of outside rear wheels and through two stake pockets, or pass wires over

axle and underneath blocks, per Sketch 4, nailed to floor with six 50-D nails in each, or tie-down plates Pattern 32 secured

with ten 10-D nails.

Overlap ends of wires and twist taut.

F

2 ea.pr.machines.

Each to consist of six strands, No. 9 ga. black annealed wire. Pass three wires around frame, spokes, or through holes in

plate of wheels, or through a suitable bracket attached to each side by side machine with at least one 1/2 in. dia. bolt, so as

to tie machines together at front and rear in the most effective manner. Overlap ends of wires and twist taut.

When single tractor is loaded separately, or with equipment other than that shown, the following securement must be used in lieu of Items "F":

Pass three wires, No. 9 gage black annealed, or 1 1/4 in. x .035 in. high tension band, through wheel, around axle or frame near front of the machine.

Pass same wires through stake pocket, or underneath one block per Pattern 5 secured to car floor with five 50-D nails, or underneath plate per Pattern 32

secured to car floor with ten 10-D nails. Twist wire taut. High tension bands must be secured to car floor with plates per Pattern 8.

Vertical holes, slightly smaller than the diameter of nails, must be drilled through blocks, Items "B", "C" and "D", and those for Item "E" when used.

Detached parts, boxed material, etc., must be loaded as far from car sides and ends as practicable, and must be secured to prevent displacement.

Tractor tires must be inflated as uniformly as possible to a minimum of 18 lbs. for two-ply tires and 27 lbs. for tires of four-ply or more.

*If so equipped, mechanical brakes must be tightly set and levers wired.

See General Rules 4, 5, 9, 14, 15, 19-A and 19-B for further details.

F-30