TM 55-2210-223-12

TO 45A2-2-14-41

2-17. STOPPING ENGINE

a.

Normal Stop.

(1)

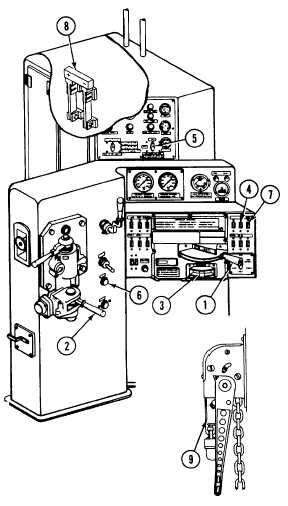

Set throttle (1) to IDLE.

(2)

Set independent brake valve (2) to FULL

APPLICATION.

(3)

Set reverser (3) to NEUTRAL position.

(4)

Set GF switch (4) to OFF.

(5)

Set throttle (1) to position 4. Run engine

at approximately 600 rpm for 5 minutes to

cool engine.

(6)

Set throttle (1) to IDLE position.

(7)

Set isolation switch (5) to IDLE position.

(8)

Check the engine crankcase oil level

while engine is idling. Oil level shall be

between ADD and FULL marks on the

CHECK WITH ENGINE RUNNING side of

the dipstick gage.

(9)

Press STOP pushbutton (6) and hold

firmly until engine stops.

(10)

Set CONT switch (7) to OFF.

WARNING

·

High voltage is used in the operation of

equipment. Do not be misled by the term LOW

VOLTAGE. Potentials as low as 50 volts may

cause death.

·

Remove rings, bracelets, wristwatches, and

neck

chains

before

working

around

the

locomotive. Jewelry can catch on equipment

and cause injury, or may short across an

electrical circuit and cause severe burns or

electrical shock.

(11)

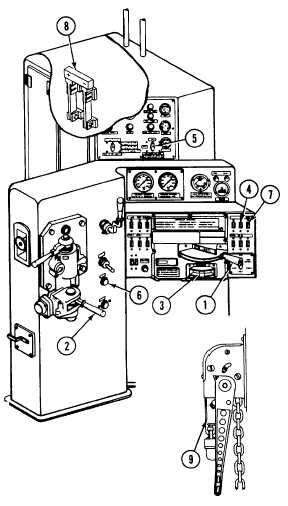

Open battery switch (8) and apply handbrake (9) if the locomotive is to be taken out of service.

b.

Emergency Stop. The engine can be shut down external to the cab by any of the following methods:

(1) Emergency fuel cut off push buttons, one located on each side of locomotive. Press until engine stops.

(2)

Manual fuel shutoff lever. Pull lever until engine stops.

2-36