TM 55-2210-224-12

2-18. COUPLING TO TRAIN AND PUMPING UP AIR (cont)

d.

When the train's air system has not been charged by a yard line and the main reservoir pressure falls below 120

psi (827 kPa), cut in the brakes as follows:

(1)

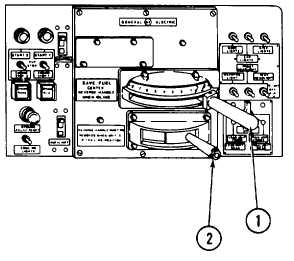

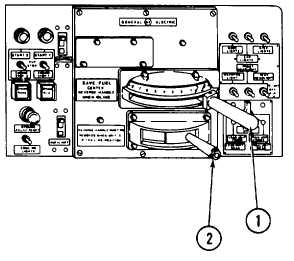

Move throttle (1) to IDLE.

(2)

Move reverser (2) to NEUTRAL position.

(3)

Advance throttle (1) slowly (not to exceed

position #4) until the required pumping rate

is reached; as main reservoir pressure

builds up, reduce the throttle.

e.

Perform train airbrake terminal test in accordance

with paragraph 2-13c.

2-19. UNCOUPLING PROCEDURES

a.

Move automatic brake valve to make a minimum of 20 psi (138 kPa) brake pipe reduction to check that brakes

are properly set.

b.

Signal brakeman to turn cutout cock on trainline hose to CLOSE.

c.

Signal brakeman to lift cutter lever and check that coupler pin is disconnected.

WARNING

To prevent injury, check that brakeman is away from trainline hoses before moving locomotive.

d.

Proceed forward or backward slowly and check that coupler and trainline hoses disconnect properly.

2-20. CUTTING OFF LOCOMOTIVE WITH OR WITHOUT CARS

a.

When the locomotive is to be cut off or the train is to be separated, leave the brakes applied with a full service

application.

b.

On completion of the full service reduction, give one short blast of the whistle to inform the trainmen they may

close the angle cocks and cut off the multiple-unit (MU) locomotive or cars. This is very important to prevent

brakes from sticking at the rear of train and to prevent cars from moving on grades.

2-21. STARTING TRAIN

Starting a train depends on the grade, weather condition, type, length, weight, and amount of slack. Make a brake test

(para 2-13) to determine if all brakes are functioning properly in the SERVICE and RELEASE positions and that no

handbrakes are set prior to starting.

2-36