TM 55-2210-224-34

3-56.

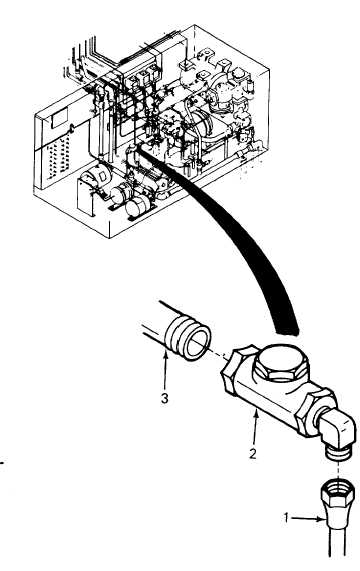

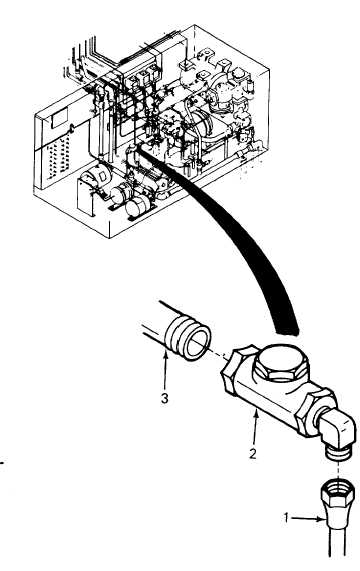

RUBBER SEATED CHECK VALVE

This task covers:

a.

Removal

b.

Installation

c.

Test

INITIAL SETUP

Tools

Tool kit SC4940-97-CL-E12

REMOVAL

WARNING

· Whenever the rubber seated check

valve is removed and installed for any

reason,

a

stationary

locomotive

airbrake test must be performed to

check that the rubber seated check

valve functions properly in the brake

equipment arrangement. Failure to

perform test may result in injury to

personnel.

· Make sure air is drained before removal

of the rubber seated check valve.

Residual air may escape and cause

injury to personnel.

NOTE

· This is a one-way valve. Note direction

of air flow.

· When removing or repairing brake

valves or components, check air lines

and pipes for corrosion, breaks, splits,

or loose connections. Repair of air

lines and piping consists of replacing

defective pipes, lines, and connections.

Refer to TM 55-2210- 224-24P for

identification of piping.

1.

Disconnect air line fitting (1).

2.

Remove rubber seated check valve (2) from pipe

nipple (3).

3-202