TM 55-2210-224-34

3-65. WHEEL (cont)

REPAIR (cont)

b. Install 30-ton (27.1 metric ton)

jack (2) on each side under roller bearing axle assembly and raise axle until wheel

clear rail (3) by 1 inch (25.4 mm).

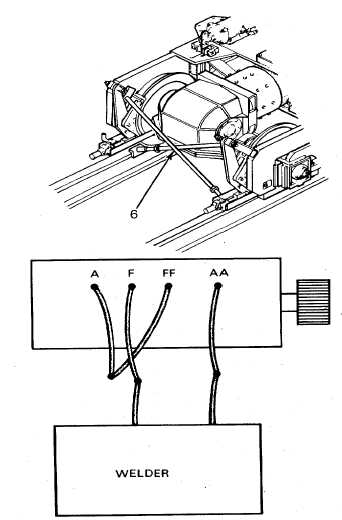

c. Disconnect traction motor leads from locomotive.

d. Connect traction motor leads to welder as shown

below.

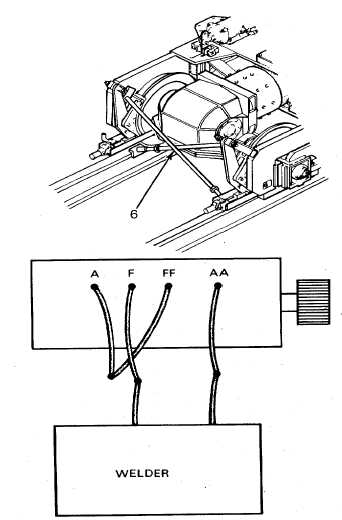

e. Install wheel turning machine (4) on rail in front of

wheel (5) and lock in place.

f. Install adjusting poles (6) from opposite rail to

machine edge and adjust to hold spread; then

tighten

clamping

bolts

and

adjusting

pole

securely.

g. Start rotation of wheel and engage wheel turning

machine with wheel. Turn wheel in accordance

with FRA regulations.

3. After wheels are turned, disconnect traction motor

leads from welder.

4. Connect traction motor leads to locomotive and tape

all leads.

5. Remove adjusting poles (6) and wheel turning

machine (4) from wheel (5) and rail (3).

6. Lower jack (2) and remove from locomotive.

7. Remove two blocks (1) from between bearings and

pedestal binders.

8. Inspect wheels in accordance with TM 55-2210-224-

12.

3-266