TM 55-2210-224-34

4-13. 6-NFR DISTRIBUTING VALVE (cont)

CLEANING, INSPECTION, AND REPAIR (cont)

CAUTION

Do not use metallic tools to clean chokes. The use of metallic tools will change

size of chokes, resulting in failure of brake valve system.

NOTE

To avoid misplacement of chokes, remove and replace one choke plug at a time.

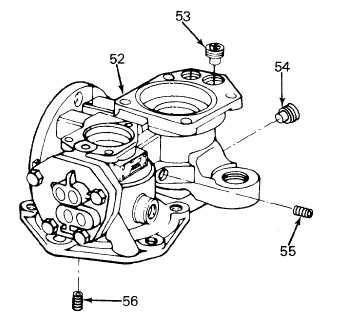

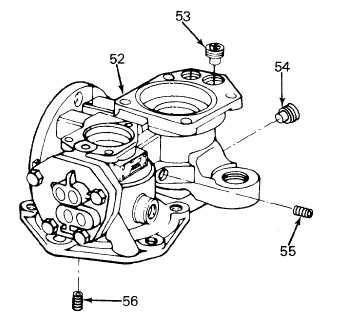

19. Clean, inspect, and repair choke plugs (53), (54), (55),

and (56) by the following:

a.

Remove choke plug and place in dry-cleaning

solvent.

b.

Inspect choke plug passage for cleanliness. Use

compressed air and remove foreign matter.

c.

Remove choke plug from dry-cleaning solvent and

dry with compressed air. Check that choke plug is

clean and unrestricted.

d.

Lightly coat threads of choke plug with compound

consisting of one part graphite and two parts oil

and install.

20. Clean, inspect, and repair slide valve bushing by the following:

a.

Check that slide valve bushing is not scratched or scored.

b.

Use plug gage and check depth of seat.

c.

If slide valve seat is scratched or scored, use a lapping compound and recondition.

d.

Use marking pigment and gage blocks and inspect for low spots on bearing surface.

e.

Remove burrs from slide valve seat

and regage.

f.

Use a depth gage and measure clearance groove. If it is less than 0.005 inch (0.13 mm) deep, use a hacksaw

blade and recut. Do not cut deeper than 0.020 inch (0.51 mm).

4-64

TM 55-2210-224-34