TM 55-2200-001-12

Change 3

Section No. 1--General Rules (Rev.-9-1976)

(3)

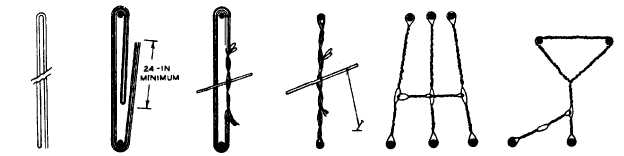

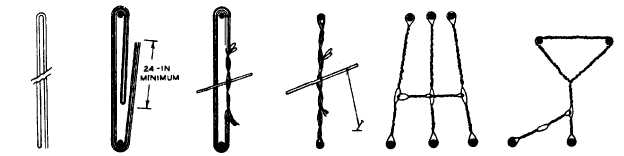

EXAMPLES FOR APPLYING 8-STRAND COMMON ANNEALED WIRE.

SKETCH 1

SKETCH 2

SKETCH 3

SKETCH 4

ALTERNATE SKETCH 4

Single strand of

Apply the strand

Hand-twist the

Finish twisting

Twister may be removed when tie-downs

wire eight times

around one point

strands ends.

taut at center

are wired to prevent untwisting as shown

length of span

of attachment

with -appropriate

above.

between tie-down

and around the

length of pipe,

points plus 8 feet.

other, having

rod, or 2-in. x

Double In half

strands overlap

2-in. lumber. Do

and double In

approximately

not remove twist-

half again.

half way between

er. Secure to car

points of attach-

floor or tiedown

ment.

point to prevent

untwisting.

Note (a).

Wires may be cut to twice the length between tie-down points, plus two feet. The cut lengths of

wire are to be placed together and wrapped around the two points of attachment as shown In

Sketch 2. Follow the procedure shown in Sketches 3 and 4, to complete the tying. Each piece of

wire cut in this manner will equal two applied strands.

Note (b).

Wires to be pretwisted or cable twisted are to be cut eight times length of span between tie-down

points, plus 8 feet. Double in half and pretwlst. Follow the procedure shown In Sketches 2, 3, and

4 to complete the tying.

(m) FLAT BARS AND PLATES

Dimensions and Breaking Strength*

Minimum

Minimum

Minimum

Size

Breaking

Size

Breaking

Size

Breaking

Inches

Strength-

Inches

Strength-

Inches

Strength-

Pounds

Pounds

Pounds

1/16 x 2

5,800

1/4 x 10

102,500

1/2 x 3

57,000

1/16 x 3 1/2

10,300

1/4 x 12

123,000

1/2 x 4

76,000

1/8 x 1

5,500

3/8 x 7/8

12,800

1/2 x 5

95,000

1/8 x 1 3/4

9,600

3/8 x 1 1/8

16,500

1/2x 6

114,000

1/8 x 2 1/2

13,800

3/8 x 1 1/2

22,000

1/2 x 12

228,000

1/8 x 3 1/2

19,300

3/8 x 1 7/8

27,400

5/8 x 1

23,100

1/8 x 4 1/2

24,800

3/8 x 2

29,250

5/8 x 1 1/8

26,000

3/16 x 2

16,100

3/8 x 2 3/8

34,700

5/8 x 1 1/2

34,700

3/16 x 5

40,350

3/8 x 2 7/8

42,000

5/8 x 1 3/4

40,500

1/4 x 1/2

5,100

3/8 x 3

43,900

5/8 x 2

46,300

1/4 x 7/8

9,000

3/8 x 3 1/2

51,200

5/8 x 3

69,400

1/4 x 1 1/4

12,800

3/8 x 4

58,500

3/4 x 3/4

20,300

1/4 x 1 3/4

18,000

3/8 x 5

73,100

3/4 x 1

27,000

1/4 x 2 1/4

23,100

3/8 x 6

87,750

3/4 x 1 1/4

33,800

1/4 x 2 3/4

28,200

3/8 x 12

175,500

3/4 x 1 1/2

40,500

1/4 x 3

30,750

1/2 x 7/8

16,600

3/4 x 1 3/4

46,300

1/4 x 3 3/4

38,500

1/2 x 1 1/8

21,400

3/4 x 2

54,000

1/4 x 4

41,000

1/2 x 1 3/8

26,100

3/4 x 2 1/2

67,500

1/4 x 4 1/4

43,600

1/2 x 1 3/4

33,300

3/4 x 3

61,000

1/4 x 6

61,500

1/2 x 2

38,000

3/4 x 6

162,000

1/4 x 7

71,750

1/2 x 2 1/8

40,400

1 x 6

210,000

1/4 x 9

92,250

1/2 x 2 5/8

50,000

1 1/8 x 6

229.500

Diameter

Minimum Breaking

Inches

Strength - Pounds*

1/2

5.200

5/8

8,100

3/4

11,700

7/8

16,200

1

21,100

1 1/8

25,800

1 1/4

32,800

1 3/8

38,600

1 1/2

46,900

D-32.3