TM 55-2210-223-12

TO 45A2-2-14-41

4-38. MAIN GENERATOR BRUSHES (cont)

ADJUSTMENT

5.

Check the thickness of the new brush in the holder for a clearance of approximately 0.004 to 0.010 inch (0.1 to

0.254 mm). Brushes with side clearance in excess of 0.010 inch (0.254 mm) will rattle, chip, or break and must be

replaced.

NOTE

Adjust each brush set to equal pressure. Unequal

pressure will cause unequal current distribution in

the brushes.

6.

Attach spring scale to each spring (6) directly over brush (5) and pull

straight up in line with the brush travel until the spring just lifts clear of

the brush. Adjust the spring pressure for 7 to 8 lb (3.18 to 3.63 kg) as

follows:

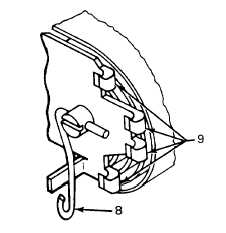

a.

Lift barrel pin (8) and increase or decrease spring pressure by

moving barrel pin to another notch (9) as required.

b.

Attach spring scale and check spring pressure.

7.

Start locomotive in accordance with paragraphs 2-10 and 2-11. Apply

softstone to commutator and run locomotive at half speed (no load)

until commutator is polished and brushes are seated.

8.

Lower cover (1).

4-89