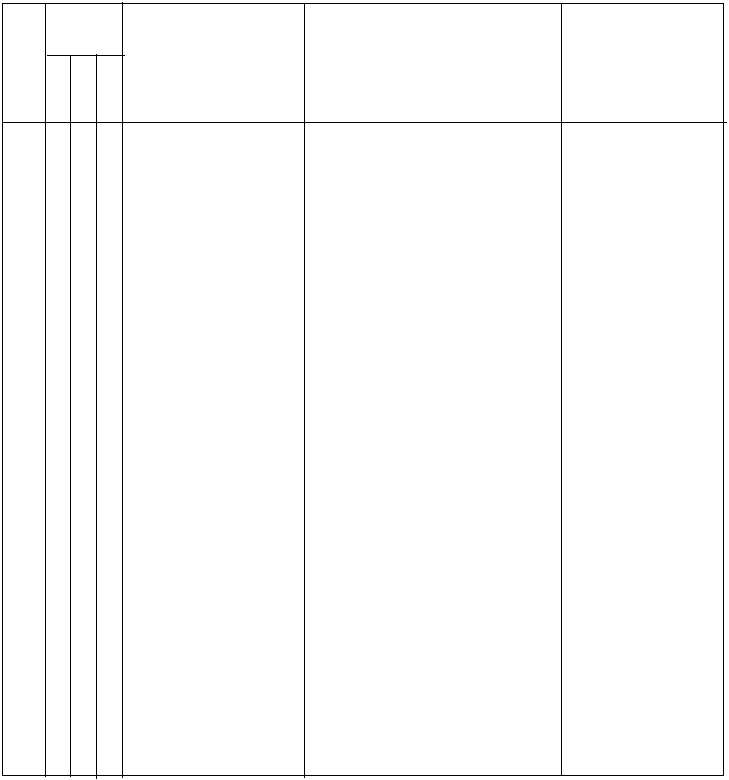

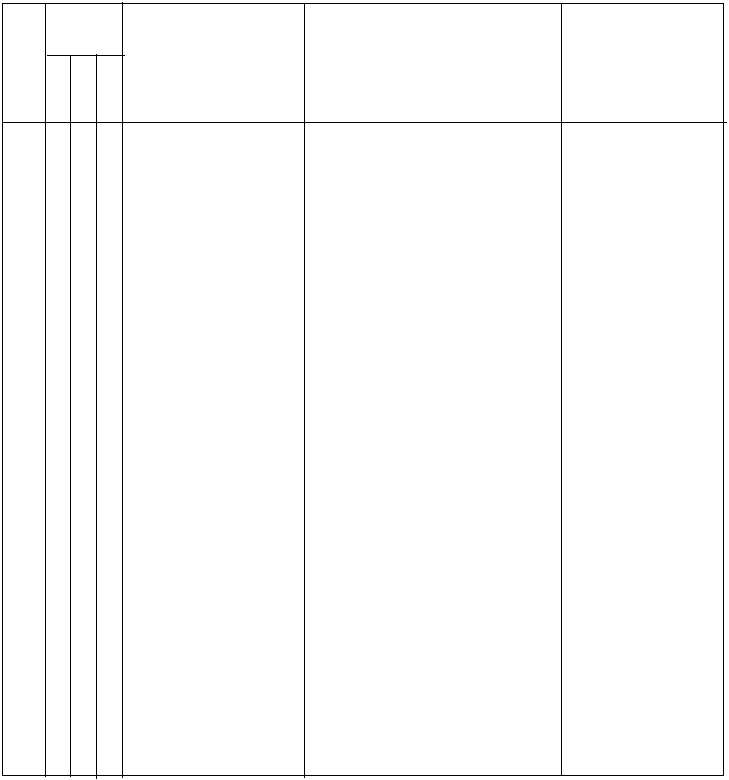

TM 55-2210-224-12

Table 2-1. Operator/Crew Preventive Maintenance Checks and Services (continued)

B - Before

D - During

A - After

INTERVAL

Item

Item To Be

Procedures

Equipment Is

No.

Inspected

Check for and have repaired,

Not Ready/

B D

A

filled or adjusted as needed.

Available If:

5

•

Brake

Check that brake cylinder piston

Brake piston

Cylinder

travel is between 3 and 6 inches

travel is not

(76 and 152 mm).

between 3 and 6

inches.

6

•

Sandboxes

Check that the sandboxes contain

Sanders are not

and Sand

sufficient sand. Add sand as

operating.

Controllers

required. Check sand controllers

for proper operation.

7

•

•

Fuel Tank,

a. Check fuel supply on fuel level

Lines, and

gage on fuel tank.

Fittings

•

b. Service fuel tank by filling

tank with proper grade of fuel.

•

c. Check lines and fittings for

There are fuel

fuel leaks.

leaks.

8

•

Cooling

Check coolant level in radiator.

There is

Radiator

Check that coolant is at proper

evidence of

level. Check for coolant leaks.

Class III leak.

If coolant is low, notify unit

maintenance.

9

•

Cooling Fan

Check for broken, loose, or frayed

Belts are

Belts

belts.

broken, loose,

or frayed.

10

•

Windshield

Check wiper arms and blades for

Windshield

Wiper

wear and damage. Check for proper

wipers do not

operation.

operate

properly.

11

•

Handbrake

Check handbrake for proper

Handbrake does

operation.

not operate

properly.

12

•

Window Glass

a. Clean windows with a soft

and Sash

cloth.

•

b. Check glass for cracks.

Windshield is

broken or

cracked.

•

c. Check sash for damage.

2-20