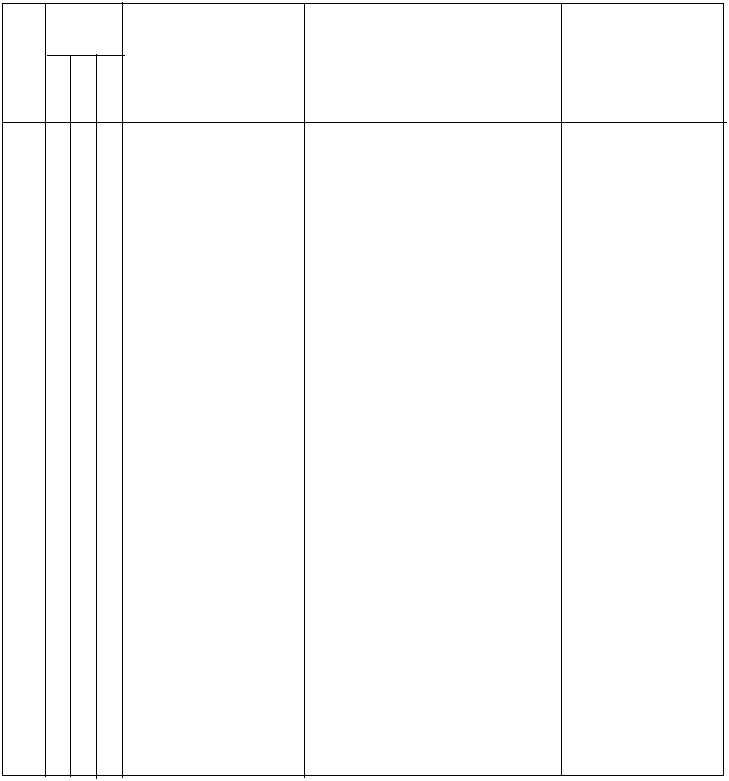

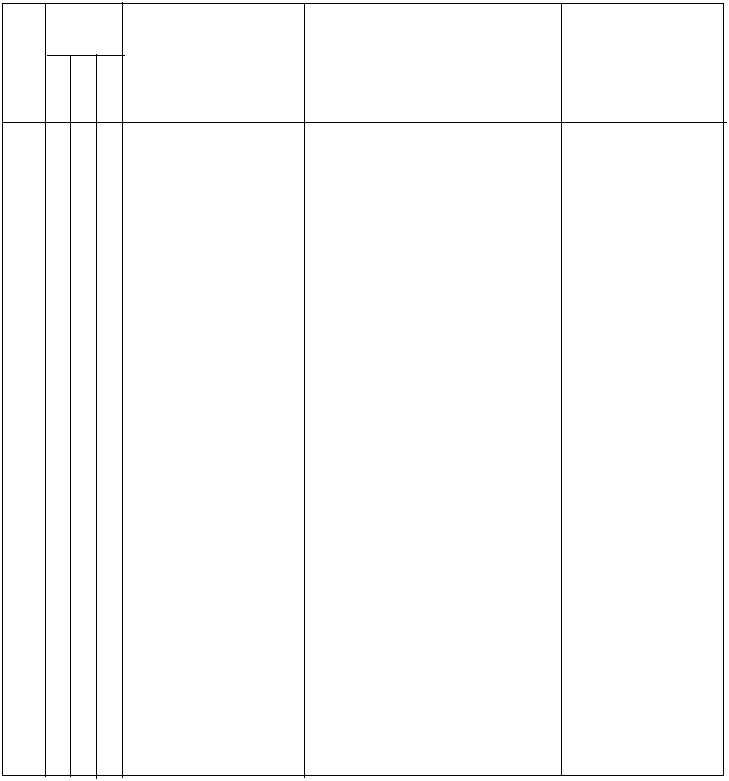

TM 55-2210-224-12

Table 2-1. Operator/Crew Preventive Maintenance Checks and Services

NOTE

Within the designated interval, these checks are to be performed in the order listed.

B - Before

D - During

A - After

INTERVAL

Item

Item To Be

Procedures

Equipment Is

No.

Inspected

Check for and have repaired,

Not Ready/

B D

A

filled or adjusted as needed.

Available If:

MAKE THE FOLLOWING WALK-AROUND

CHECKS:

1

•

Exterior of

a. Visually inspect the following

Any component is

Locomotive

items for proper operations,

damaged that

cracks, breaks, broken welds, and

would impair

damage:

locomotive

operation.

Cab and engine hood doors and locks

Handrails and uprights

Cutter levers and steps

Truck Assemblies

(Check side bearing clearance)

No clearance is

Couplers

apparent.

Coupling mechanism

•

b. Inspect under locomotive for

There is

evidence of fluid leakage (fuel,

evidence of

oil, or coolant).

Class III leak.

2

•

Foundation

Inspect foundation brakes for

Parts are loose

Brakeshoes

loose or dragging parts

or dragging

and Brake-

heads.

3

•

Trainline Air

a. Check trainline air hoses for

Air hoses are

Hoses and

cracks, breaks, and deterioration.

damaged.

Fittings

Check glad hands and gaskets for

damage.

b. Check expiration date on

Expiration date

trainline hoses. Replace 8 years

past due.

from date.

4

•

Wheels

Inspect wheels for defects and

Wheel is

worn or missing brakeshoes. Check

damaged. Brake-

that brakeshoes are in proper

shoe is worn or

alinement.

missing.

2-19