(6) Precautions.

(a) Use long fibre wool waste. Keep

waste TEASED UP.

(b) Use waste that has been well

saturated with clean oil.

(c) Use a clean oil of high quality and

correct grade.

(d) Keep oil and waste in closed cans.

(e) Pour oil in the oil well.

(f) See that oil box lids are closed.

c. Gear Lubrication. The teeth of the gear and

pinion should never appear dry, but should be well

covered with lubricant.

40. Main Journals

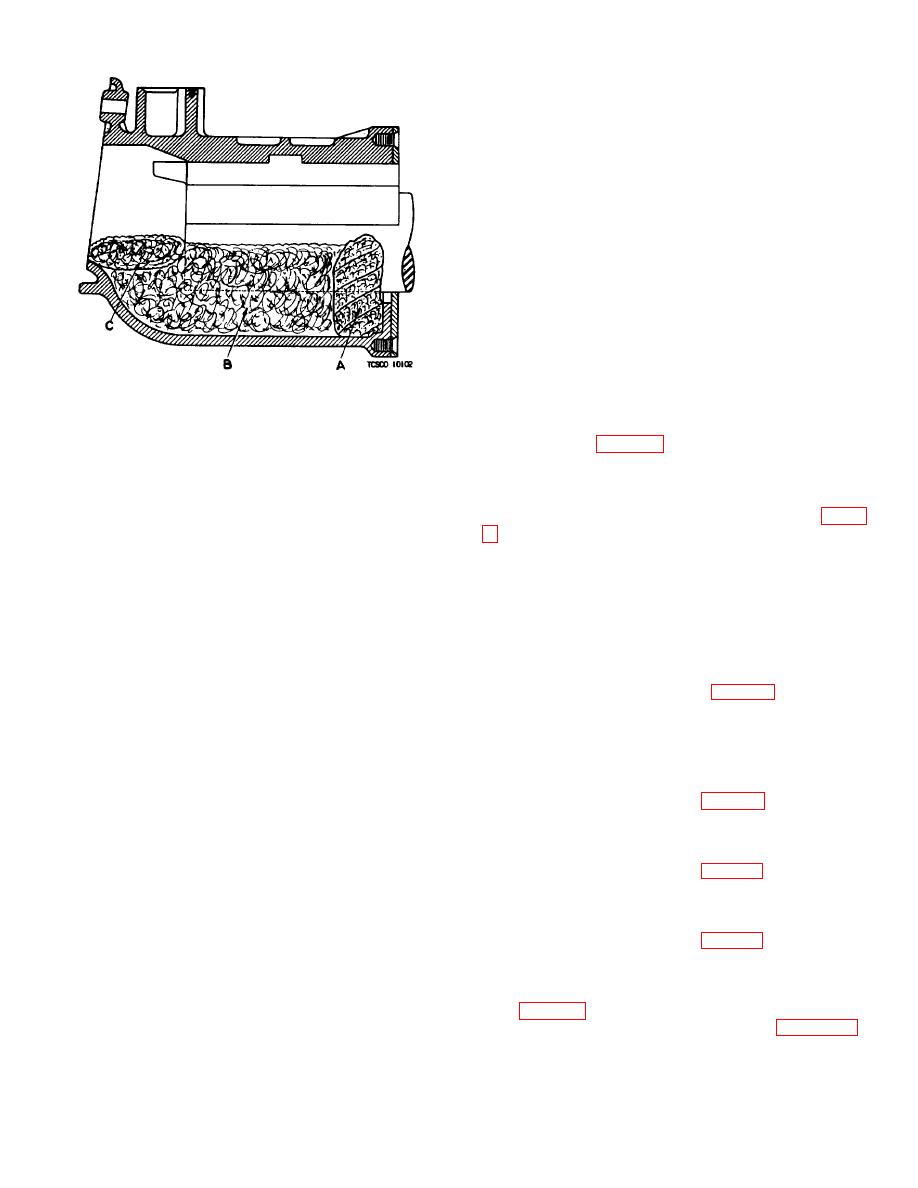

Figure 7. Method of packing journal boxes.

a. Pack the main journals as frequently as service

conditions may require.

poured into the well it will overflow;

b. Use a good grade of wool waste soaked in oil,

this is a waste of oil.

as specified on figure 5, for at least 24 hours and

drained for about 6 hours. Keep the temperature of the

(b) The height of oil measured from the

oil and room in which the waste is drained at about 60

bottom of the chamber, using a

F.

flexible gauge, should be as follows:

1. Maximum 2.375"

2. Minimum 1.125"

and bottom of the box as shown. Place packing marked

(4) Inspection and oiling periods. Bearings of

B in position with moderate pressure against the journal

this type, if in good condition, properly

but sufficient to make good contact, applying the waste

packed with ling-fibre wool waste, and

somewhat looser at the sides of the box to prevent

supplied with a good grade of oil, should

wiping effect. The packing should not extend higher

run from 1,000 to 1,100 miles between

than the center of the journal.

oiling periods. It is advisable for each

d. After packing is completed, pour free oil over

operator to work out in actual service the

the waste along the sides of the box near the center.

most suitable oiling schedule to fit the

Place a wad of semidry waste C, figure 7, between the

operating conditions of his equipment.

end of the journal and front end of the box as shown, the

Such a schedule may be determined

purpose of which is to serve as a dirt collector and can

largely by the system of inspection of the

easily be renewed as required.

other equipment on the traction unit.

When inspecting bearings, carefully wipe

all dirt from the oil box lid before it is

41. Air Compressor

opened.

Refer to TM 55-2034 and figure 5 for lubrication

instructions.

(5) Repacking periods. Repack the bearings

after they have been in service for 50,000

42. Airbrakes

miles as a maximum, or at least once a

Refer to TM 55-2029 and figure 5 for lubrication

year. When repacking bearings, remove

instructions.

all the waste and discard that which is

glazed and charred; refill the bearings

43. Diesel Engines

with good, clean, oil waste to which has

Refer to TM 55-1046 and figure 5 for lubrication

been added sufficient new waste to allow

instructions.

for any old waste discarded or destroyed.

About once in three months, TEASE UP

44. Miscellaneous Equipment

the waste in the bearings to make it more

efficient.

for all equipment not included in the above paragraphs.

20