TM 55-2210-224-34

3-23. CRANKING CONTACTOR (cont)

CLEANING, INSPECTION, AND REPAIR (cont)

f.

Armature (43).

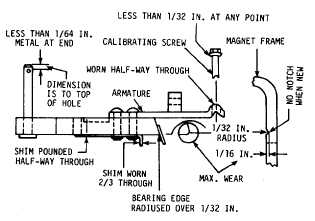

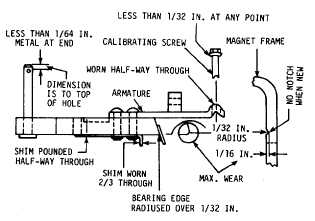

(1) Inspect the armature for a

rounded bearing edge or

uneven wear. If the armature

bearing edge is worn beyond

1/32 inch (0.793 mm), replace

the armature.

(2) Inspect the armature bracket

(extension on the end of the

armature to which the

calibrating spring is attached.

(3) Inspect the pin over which the

contact pressure spring fits.

Replace the pin if less than

1/64 inch (0.396 mm) remains

between the hole and the end

of the pin.

(4) Inspect the armature shim. Replace shim if the portion between armature and magnet frame is pounded

more than halfway through or if the short, bent-up portion is worn more than two-thirds through.

g.

Armature stop (48). Inspect the armature stop for grooving and uneven wear. If the armature stop is grooved

or worn more than 1/16 inch (1.58 mm) at the bearing edge of the armature, replace the armature stop.

h.

Calibrating spring (30). Inspect calibrating spring and replace spring if it is cracked, corroded, notched on the

end hook, or has lost its tension.

i.

Contact pressure spring (33). Inspect pressure spring and replace spring if cracked, corroded, notched on end

hook, low on tension, annealed, or showing signs of electrical damage.

j.

Stationary contact tip support (17).

(1) Inspect contact support for discoloration caused by overheating and for cracks. Replace contact if any of

the above conditions are found.

(2) Inspect the tapped hole for signs of burred, stripped, or damaged threads. Replace the contact if tapping

of the hole will not restore the threads.

k. Base (56).

(1)

Inspect base (56) for soundness. Replace base if it appears to be oil soaked or cracked.

(2)

Paint base (56) with one or two coats of insulating varnish.

3-83