TM 55-2210-224-34

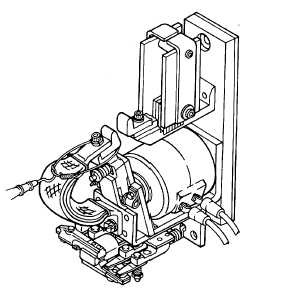

3-23. CRANKING CONTACTOR (cont)

ADJUSTMENT (cont)

35. Measure tip pressure as follows:

a. Measure initial pressure as follows:

(1)

Block the armature (not the tip lever) so the contact nearly touch.

(2)

Measure the pull required to just move the contact-tip arm against the contact pressure spring.

(3)

Check for a pull of 2 to 4 lb (0.908 to 1.816 kg).

b. Measure final pressure as follows:

(1)

Block the armature in the closed position.

(2)

Measure the pull required to just separate the contact tips.

(3)

Check for a pull of 5 to 8 lb (2.267 to 3.632 kg).

c. If the pressure measurements are not correct, check for the following conditions:

(1) Low initial pressure defective

contact pressure spring, worn

spring seat or washers, or

worn stop.

(2) Low final pressure defective

pressure spring, low wear

allowance, or badly worn tips.

TEST

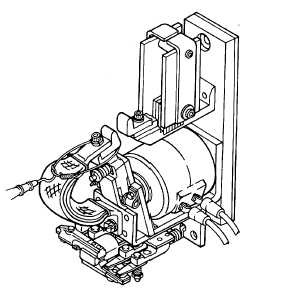

36. Measure and adjust coil operating

current as follows:

a.

Use a multimeter and measure

resistance of coil. Indication shall

be between 5.76 and 7.04 ohms.

b. Connect power supply and ammeter to coil.

c.

Apply current and increase slowly until contactor picks up. Check that the contactor picks up without

hesitation, that is, in one quick motion including the contact wipe. The current measured shall be 1.8 to 2.2

amperes.

d. Adjust calibrating screw until proper value of current is indicated.

37. Manually operate interlock contacts. Use a multimeter and check resistance of contacts for infinity while open and

continuity while closed.

3-88