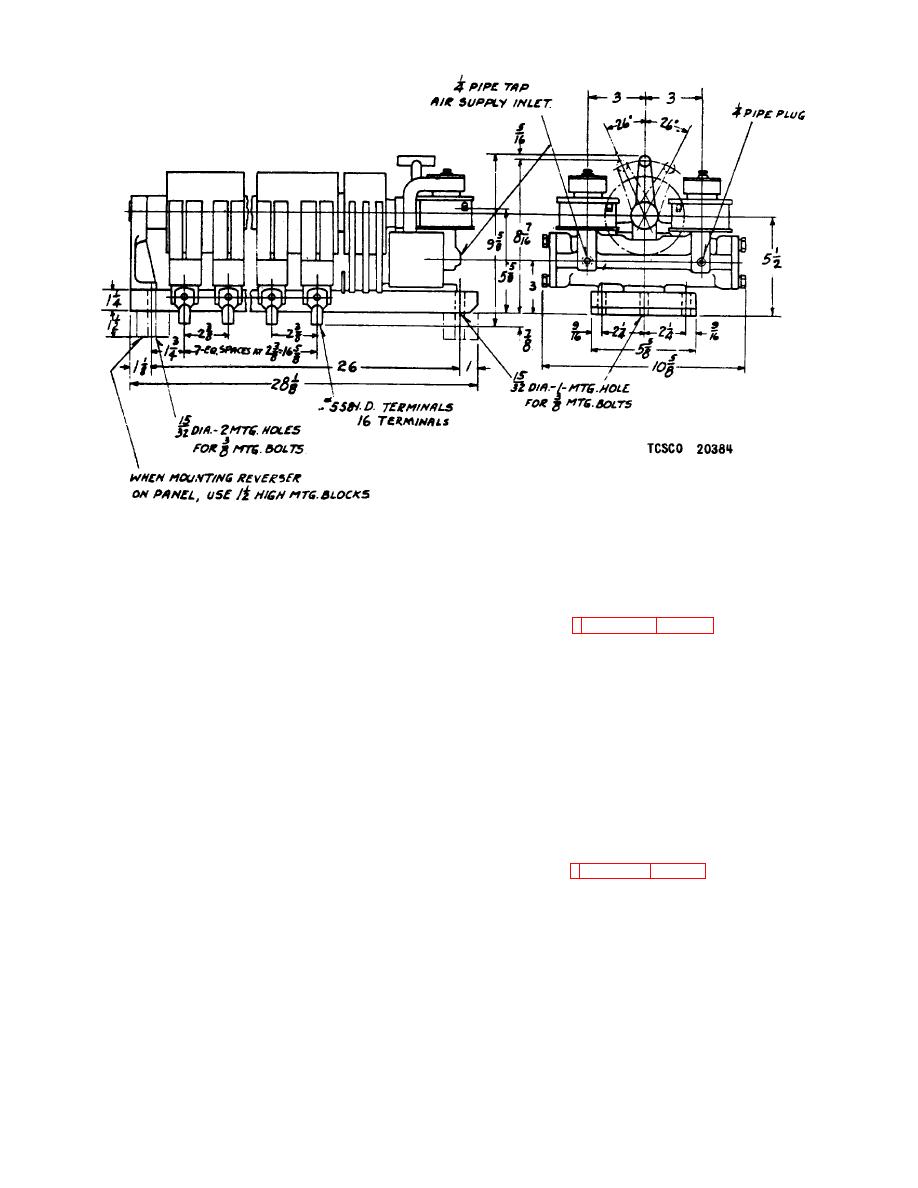

Figure 21. Reverser outline.

being

alternately

energized

or

the admission of air to and the exhaustion

deenergized depending upon the direction

of air from the air-operated cylinders.

of motion necessary.

Magnet valves fall naturally into two

general classifications as to operating

(4) Figures 22 and 23 illustrate the general

principle: namely standard and inverted

principle of magnet valves, using a typical

valves.

cross section of a standard valve, the

chief distinction between the standard and

(2) The standard valve when energized,

inverted valves being that in a standard

admits air from the pressure line through

valve one bushing with two seats (upper

a small port or seat allowing the air to

and lower) and two valve stems are used,

pass through the valve and into the air

while in an inverted valve two bushings

cylinder which actuates the complete

and one floating valve with two faces

piece of apparatus. In this valve the full

actuated by a pushrod and operating

pressure of the air line or reservoir acts

between the bushings are used. The

continuously in the cylinder, as long as

construction of corresponding valve parts

the magnet coil is energized, while

is similar and the following description,

another valve on another seat prevents

therefore, applies to all the valves.

the air from escaping through the magnet

valve exhaust port.

(5) Figures 22 and 23 show the diagrammatic

cross-sectional view of a standard magnet

(3) The inverted valve energized, acts to shut

valve with the operating parts in the

off the air from the supply line and allows

position which they occupy when there is

air to escape from the cylinder through an

no current passing through the coil.

exhaust port in the magnet valve.

Under this condition the spring (a) pushes

Sequence switches usually use both types

the valve (b) up against the seat (c) and

of valves at the same time, due to the

prevents any air from passing from the

opposed direction of travel of the pistons

control air supply to the operating cylinder

in the air cylinder, the magnet valves

50