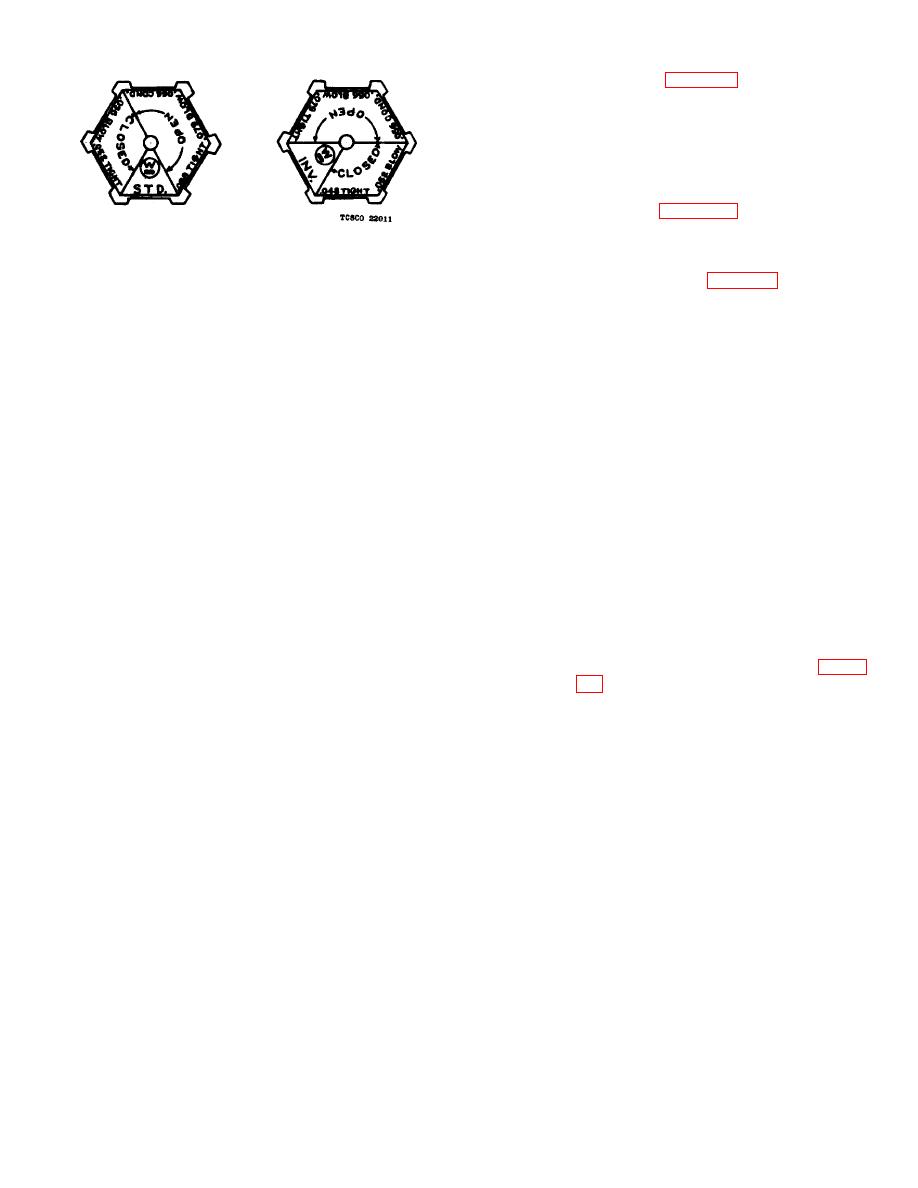

simple gage, figure 24, is employed. This

gage is used for both standard and

inverted valve by turning it over,

depending on type of valve to be

checked.

e. Checking and Adjusting Standard Valves.

(1) Upper valve stem.

and adjust the final gap and length

Figure 24. Valve setting gage.

of new upper valve stems. Remove

the magnet cap and insert the gage

the order of their usual liability of

as shown on figure 25. Flat-file the

occurrence.

top of the upper stem until the

(a) Dirt on the valve seat (e).

0.056-inch gage will admit air to the

cylinder with a slight leak out the

(b) Weak battery or low voltage applied

exhaust and the 0.052-inch gage

to coil.

will close the exhaust valve tight.

(c) Dirt under the magnet armature (h).

The final air gap is then between

(d) Valve stem (k) worn down so that

the two, or approximately 0.054

armature strikes the core (m) before

inch.

New stems have excess

the valve seats.

length and should be ground to a

(2) To remove stem (k) it is not necessary to

tight seat before adjusting the gap.

shut off the air. First remove the cap over

Directions for grinding are included

the armature and lift out the armature

in h below.

which is not fastened in any way. Next

(b) In service, it is permissible to allow

place a finger on one hand over the

the upper stem and seat to wear

magnet valve exhaust port (f) and press

until the final gap is approximately

down on top of the valve stem with a

0.032 inch. The 0.066-inch gage

finger of the other hand and then raise the

will at this point fail to unseat the

finger quickly. The valve stem will be

lower valve to admit air to the

raised by the air pressure and can be

cylinder and the upper stem must

readily lifted out and the end of the valve

be stretched by peening or a new

wiped clean.

stem used.

(3) A weak battery will sometimes give a

(2) Lower valve stem. The same gage, figure

sufficient pull to unset the lower valve but

not enough to close the exhaust. The

has been adjusted, to adjust the travel

obvious remedy is to charge the battery.

and the length of the lower valve stem.

(4) Another possible cause of a blowing

Use the 0.088-inch gage.

This will

exhaust valve, i. e. worn down stem (k),

probably cause the valve to unseat and

is very unlikely to occur until after the

blow due to excess length of the lower

equipment has been in service for several

stem. The upper end of lower stem

years. If this stem is found to be too short

should then be flat-filed until the 0.088-

it can be slightly stretched by "peening"

inch gage will not touch but the 0.070-inch

the shank.

gage will unseat the lower stem. The total

d. Valve Gaging.

gap is then approximately 0.086 inch and

the travel is 0.086 inch minus 0.054 inch

(1) In order to obtain satisfactory operation

or 0.032 inch. In service, it is permissible

from the electro pneumatic valves, it is

to allow the lower stem to wear as long as

necessary to maintain the "travel of the

the condemning gage 0.066 inch makes

valve" and the final gap between the

the lower valve blow when the upper stem

magnet armature and core, within certain

is new. If it does not, the travel has then

limits.

reached 0.012 inch and the lower

(2) After a considerable period of service the

valves wear down and it is necessary to

refit or replace them.

In order to

accurately determine their condition a

52