the top of the magnet valve and releasing

it quickly several times. If the blowing

persists shut off the air from the apparatus

and unscrew the plug at the bottom of the

magnet valve. Carefully lower the plug

straight down and the spring and lower

valve will drop down with it. Wipe the

valve perfectly clean and with a small

stick and piece of cloth also clean the

valve seat.

(2) When replacing the lower valve, spring,

plug or valve nut, first remove the cap

over the armature so that in case the

valve stem does not properly enter the

hole in the stem (k), it is free to be lifted

by the advancing stem instead of being

damaged. If the inlet or exhaust valve is

not tight, the difficulty can sometimes be

overcome by inserting a small screwdriver

in the top slot and spinning it a few times

on the seat.

c. Exhaust Valve Leakage.

(1) In case a standard valve "blows" through

the exhaust port when the coil is

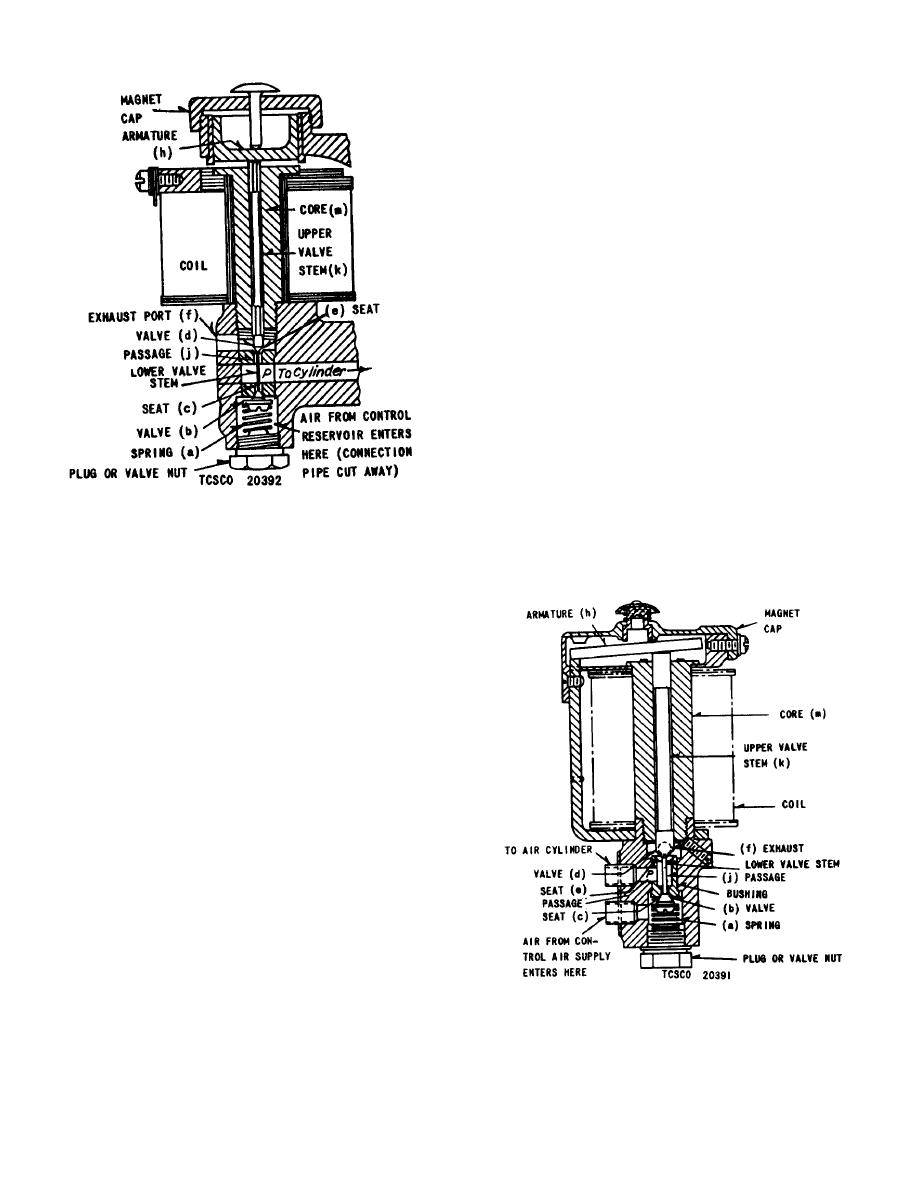

Figure 22. Cross section of open-coil type standard

energized it is a sign that the exhaust

magnet valve.

valve (d) is not seating properly on the

seat (e). This may be due to any one of

the following causes which are mentioned

The spring (a) not only closes the valve

in

(b) but at the same time lifts the valve (d)

off its seat (e) and leaves a clear opening

for the escape of air from the operating

cylinder through the passage (j and f) to

atmosphere. When the magnet coil is

energized the armature (h) pushes down

on the stem (k), opens the valve (b) and

admits air from the supply to the operating

cylinder through the passage (p), and at

the same time closes the exhaust valve

(d).

(6) The maintenance procedure for all valves

is practically the same.

b. Inlet valve leakage.

(1) Occasionally a valve will "blow" (i. e.,

give out a hissing sound) due to leakage

of air, if this occurs when the magnet coil

is de-energized and the air blows out of

the magnet exhaust port (f), it is an

indication that the lower (inlet) valve is not

seating properly. This trouble is caused

generally by the presence of a little dirt on

the valve seat and in most cases can be

"cured" by pressing down the pinion and

Figure 23. Cross section of open-coil type standard

co-ordinated magnet valve.

51