base. For care of magnet valves, refer to paragraph 88.

b. Fingers.

(1) The pressure of the fingers on the

contacts should be approximately 5 to 6

pounds for the main contacts and 11/2 to

3 pounds for the interlock fingers. The

finger pressure can be measured by

means of a small spring balance attached

to a piece of bent metal strap which can

be slipped under the finger.

(2) If the segment under the fingers is to be

cleaned, do not lift the fingers far enough

off the drum surface so as to strain the

spring and reduce the tension; such a

common source of trouble should be

carefully avoided.

(3) If the contact fingers and drum segments

are allowed to operate completely dry

they will start to cut in a comparatively

short time. Spread a little light machine

oil occasionally over the drum contacts

with a piece of cloth, and operate the

drum a few times; wipe off any surplus oil

around the contacts or segments.

Oil the drum bearings at intervals with a

light oil.

(4) The finger pressure is varied by changing

the bend in the finger spring where the flat

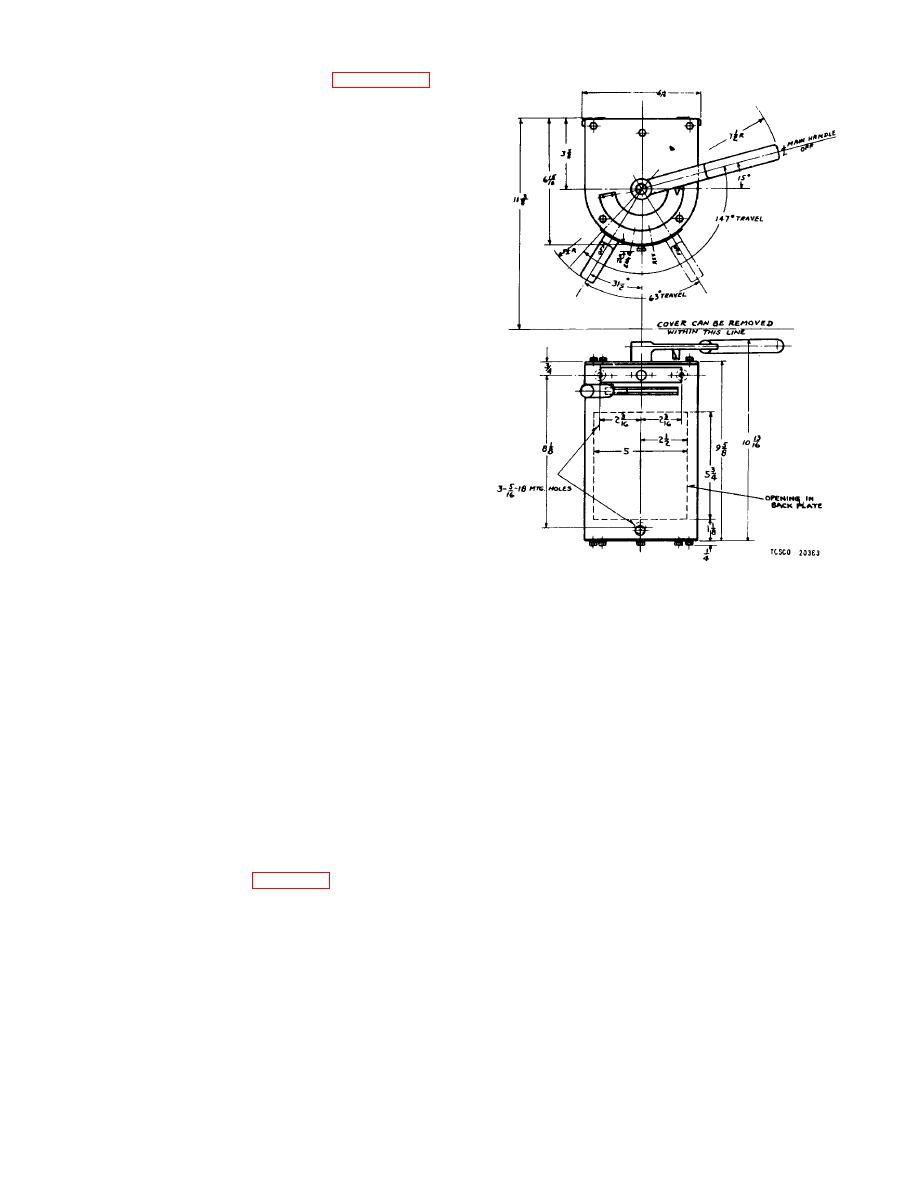

Figure 20. Control outline.

spring type finger is used. To increase

the pressure, it is necessary to remove

the finger by removing the screws which

bearings in place and lift out the drum.

hold it in place, and give the spring a little

Next the tap bolts in each cylinder head

greater set. The fingers will maintain their

should be taken out and the head

pressure for a long period of time if they

removed, care being exercised not to

are not abused.

Fingers of the

injure the paper gaskets which are under

compensated type cannot be adjusted for

them. Remove the nut and lockwasher on

spring tension. A damaged finger must

one end of the piston rod, after which the

be replaced.

piston rod with one piston attached can be

c. Cylinder Maintenance.

shoved out of the cylinder by pushing on

the end of the piston rod with a

(1) Pistons are properly oiled when the

screwdriver. The remaining piston in the

reverser is assembled at the factory and

cylinder can easily be pushed out from the

ordinarily will function for a long period

other end. It is not advisable to push the

(six months or a year) before it requires

piston past the opening in the center of

any additional lubrication.

When

the cylinder as the leather may be injured.

lubrication is necessary, use only oil as

specified on figure 5.

The use of

unsuitable oil will lead to trouble from

88. Magnet Valves

gummed pistons which will cause sluggish

a. General Description.

action or sticking.

(1) The sander and engine shutdown are

(2) In order to remove the piston rod and

provided with magnet valves which

pistons it is necessary to first remove the

govern

four tap bolts which hold the drum

49