with 35 volts across AG to N (make AG

should not drop more than 3/6 inch due to

positive). Coil should be warm.

its own weight when the main panel is in

position on the locomotive.

(7) Set contact spring tight as possible and

still permit relay to seal at pick-up voltage

(5) Set reverse current relay armature gap to

without fail. Relay must not float in or out.

1/16 inch at center of coil core. Adjust

stationary contacts to just touch the

(8) With 32 volts across AG to N, pass

movable contact and lock them. Re-

current through relay B3 to AG. (Make B3

adjust armature gap to 5/32 and lock it.

positive.) Relay should drop out at 4 to 12

Contact gap should then be 13/64.

amperes without floating.

(6) Adjust armature spring so relay closes

Section XI. SPEED INDICATING EQUIPMENT

installation measure the wheel diameter and set the

wheel-wear adjustment in the transformer-resistor box.

Refer to paragraph 98.

c. Indicator.

(1) The temperatures where the indicator is

mounted should never exceed 140 F.

Indicator will operate more accurately at a

temperature of 75 10 F. Figure 32

shows mounting dimensions.

(2) Handle indicator with care to avoid

damaging jewel bearings.

Do not

hammer on the panel on which the

indicator is mounted.

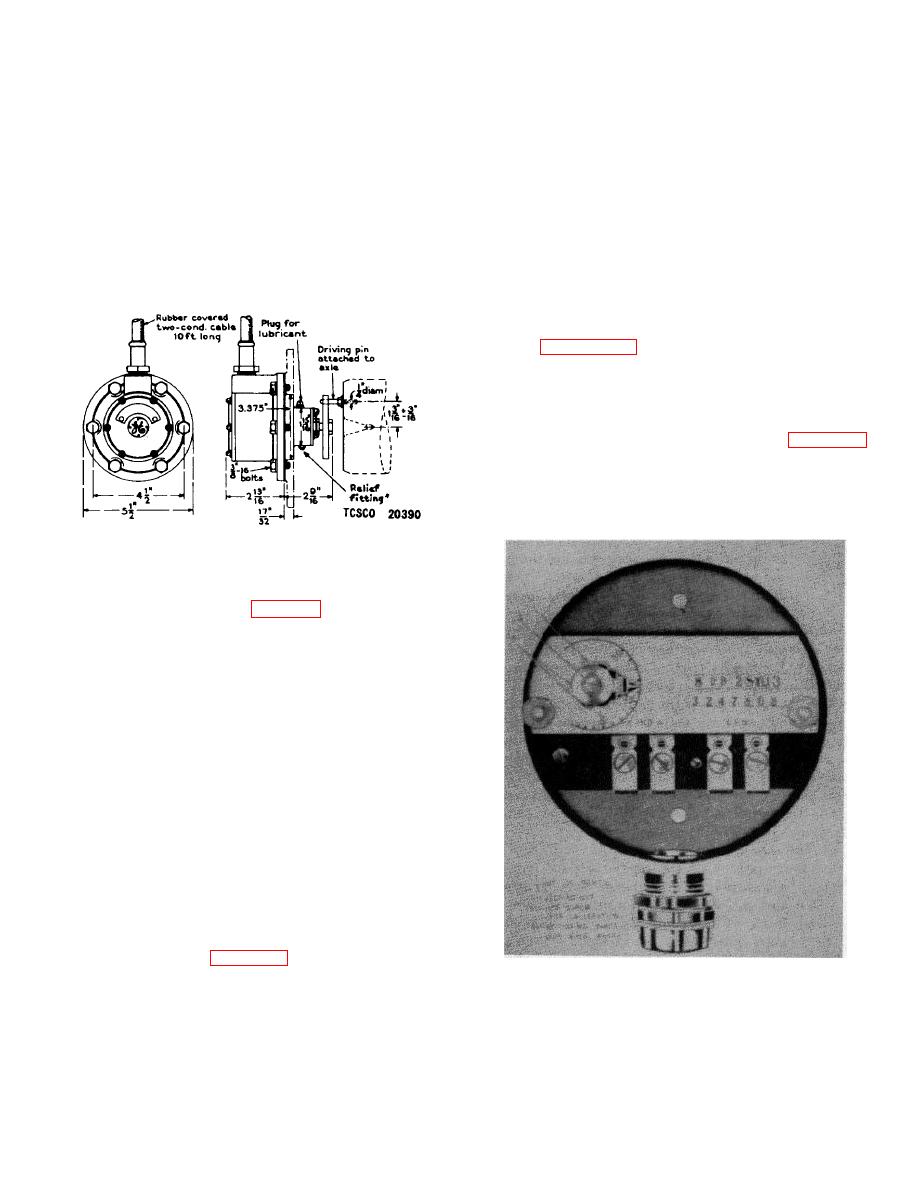

Figure 31. CM-4 Generator assembly method.

97. Installation

a. Mounting Generator. Install a driving pin on the

end of the axle as shown in figure 31. Bolt the special

journal box cover into position. Turn the generator rotor

so that the driving arm engages with the pin on the axle.

Carefully position the generator against the journal box

cover checking that there is clearance between the pin

and generator. Bolt the generator, with the drain hole

down, to the journal box cover using standard 3/8-16

bolts. Check that the generator shaft is concentric with

the wheel axle. Gaskets are provided to make an oil-

tight connection. Place a piece of 3/4-inch hose,

clamped at both ends, over the generator cable for

protection.

b. Transformer-Resistor Box.

Mount the

transformer-resistor box in any convenient location

which is protected from dirt and moisture. Particular

attention must be paid to the temperature of tile site. It

is recommended that the site have a temperature range

of 75 10 F. The temperature should never rise

above 120 F. Temperatures up to 120 F. will not

damage the box but will introduce temporary errors in

proportion to the rise. Figure 32 shows the mounting

Figure 32. Transformer-resistor box with

dimensions of the transformer-resistor box.

On

dimensions.

62