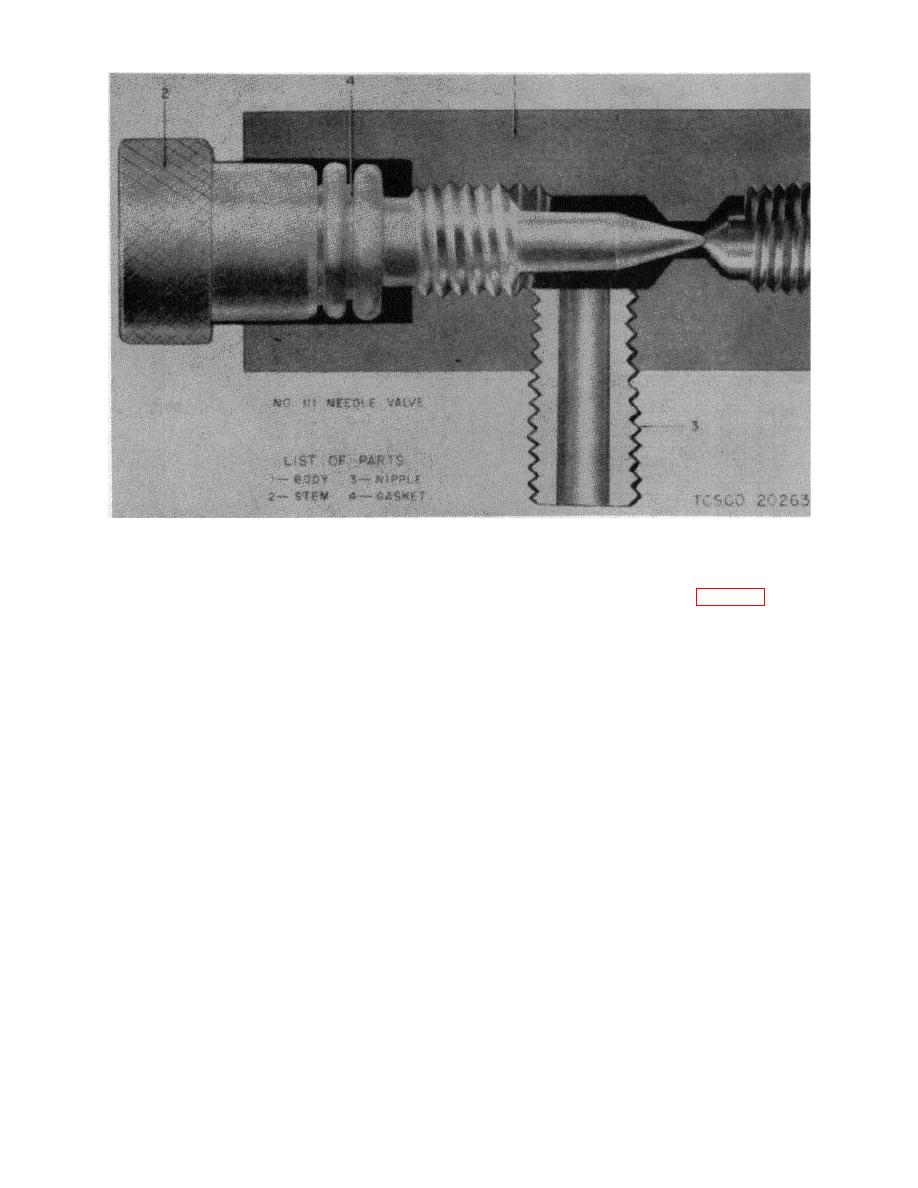

Figure 40. Bell ringer needle valve.

minimum and fitted with oversize piston 1.0248 inch

b. To disassemble valve drive out handle pill (6)

diameter maximum, 1.0240 inch minimum at port end.

and remove handle (3). Unscrew cap (4) from body (1)

c. If clapper fulcrum pin shows excessive

and push out rotor (2). Refer to figure 39.

clearance in the oilite bearings (7), pin and bearings

c. Seating surfaces on rotor (2) and body (1) may

should be replaced. After bearings are pressed in place,

be lapped in, or refaced, many times before valve has

peen over metal on outside to hold bearings in place.

to be condemned.

Ream bearings to 0.3760 inch diameter after pressing in

d. When seats are refaced remove all sharp edges

if fulcrum pin does not revolve freely.

Before

and burrs. Renew gasket (7) if damaged.

reassembling, all parts must be clean. Lubricate with

light oil and test assembled ringer.

107. Bell Ringer Needle Valve

To adjust cadence, close needle valve screw and

106. Bell Ringer Operating Valve

gradually unscrew until proper cadence is acquired. Do

a. An occasional drop of light oil is all this valve

not unscrew more than two full turns as opening through

will require to provide years of trouble-free service.

body to ringer is maximum. The O-ring gasket prevents

air leaks and holds valve adjustment.

Section XIV. OIL FILTER

when loosened, swing away from the cover so as to

108. Description

permit its removal easily. The cover is sealed by means

a. The lubricating oil filter has a radial flow

of a wide vellumoid gasket.

repackable wastex element. The cover is held to the

top ring by means of four steel eyebolts. These bolts,

67