resistor box setting, if necessary.

To make the

adjustment, loosen the locking nut, taking care not to

disturb the setscrews on the hub of the dial, and set the

dial to correspond with the diameter of the wheel driving

the generator. Tighten the locking nut. Check setting to

see that it has not been disturbed when locking.

b. Zero-Set. The indicators are equipped with an

external zero-adjusting screw in the front of the case.

The pointer may be set on zero, when the indicator is

de-energized, by turning the zero adjuster with a

screwdriver at the same time gently tapping the front of

the cover.

particular transformer-resistor box and the two must

always be used together. However, generators of the

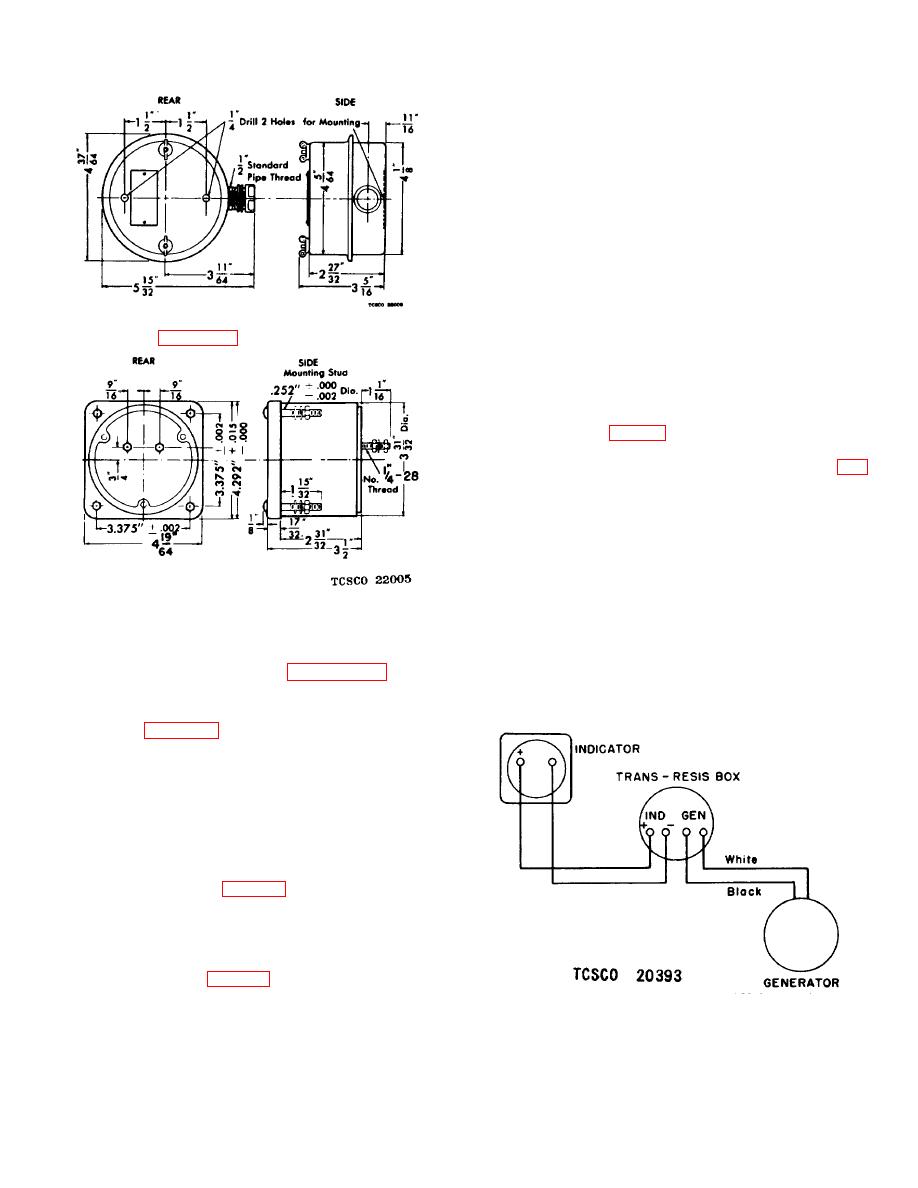

Figure 32 - Continued.

same type may be interchanged with no effect on the

accuracy of the system. Check the speed-indicator

calibration occasionally by observing the time over a

measured mile.

To check the operation of the

equipment when it is removed from the locomotive, a

calibration curve (fig. 35) shows the relation between

generator rpm and instrument indication in miles per

hour for wheel diameters between 30 inches and 40

inches.

d. Generator. It is important that ,a watertight joint

be maintained at the point where the cable enters the

generator. Do not remove the leads from the generator

unless it is necessary to replace either generator or

leads. If it is necessary to remove the generator,

disconnect the leads at the connection box.

On

Figure 33. Speed indicator mounting dimensions.

replacing the cover plate of the terminal box, cement

the cover gasket in place with gasket cement. Take

(3) Check that the pointer is on the zero

every precaution to see that no water is allowed to enter

mark. If it is off, make the zero-set

the generator.

adjustment. Refer to paragraph 98.

e. Lubrication.

The generator is permanently

d. Connections.

lubricated; therefore, it will be necessary to lubricate it

(1) Make connections in accordance with

only at overhaul with high-temperature grease.

stranded copper wire.

(2) Make a good ground connection between

the locomotive frame and the truck on

which the generator is mounted. The

resistance of the ground circuit may be

checked by temporarily disconnecting the

auxiliary ground lead to the transformer-

resistor box at the point X on connection

diagram (fig.

ohmmeter. The resistance as measured

at this point should be less than 10 ohms.

98. Maintenance

diameter at regular intervals and adjust the transformer-

Figure 34. Wiring diagram for type CM-4 generator.

63