TM 55-2210-224-34

3-64. TRACTION MOTOR ASSEMBLY (cont)

DISASSEMBLY (cont)

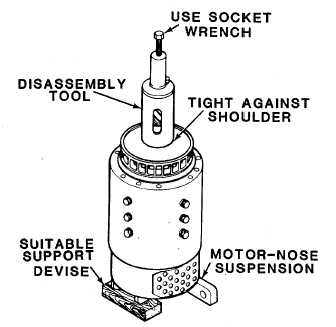

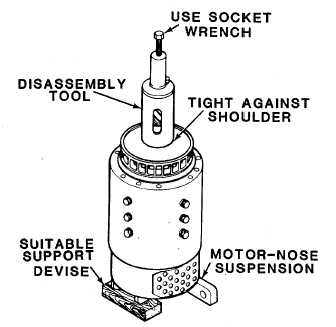

WARNING

Pinion gear will snap off suddenly

under approximately 50-90 tons of

pressure. Personnel must stand to

either side of motor when pulling

pinion gear. Injury or death could

result.

NOTE

Pinion gear on the traction motor and

ring gear in the gear box are a

matched set and must be removed

and installed together. If one is

replaced, both must be replaced.

9.

Pull up evenly on bolt to force piston down into

pinion bore. When sufficient force has been built

up, pinion will break loose from pinion bore.

Approximately 50-90 tons pressure is required to

break pinion loose.

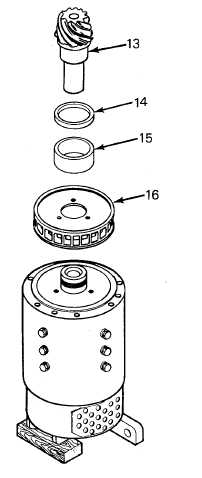

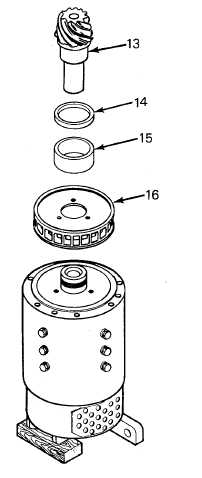

10.

Remove disassembly tool kit and remove hypoid

pinion (13).

11.

Use a puller and remove spacer (14) and inner

bearing race (15).

12.

Mark hub of fan (16) and head of armature (37) so

fan can be mounted in the same location at

assembly.

13.

Place motor in horizontal position.

Use puller

from disassembly tool kit and remove fan (16)

from armature (37).

14.

Remove four capscrews (17), lockwashers (18),

clamp (19), and wire bracket (20).

15.

Remove two covers (21). Tag and disconnect

brush holder leads. Remove four capscrews (22),

lock-washers (23), clamps (24), and brush holders

(25). Remove brushes from brush holders. Refer

to TM 55-2210-224-12.

16.

Wrap insulating paper around commutator to

prevent damage.

3-236