TM 55-2210-224-34

3-64. TRACTION MOTOR ASSEMBLY (cont)

DISASSEMBLY

2.

Install motor lifting bracket (9) and place motor on floor in a vertical position adequately supported on motor-nose

suspension and suitable support device.

NOTE

The disassembly tool kit and the following procedures are recommended for removal of the hypoid

pinion. However, any tool that does not cause damage to the pinion or other parts, and any method

that can be accomplished in a safe manner, may be used.

3.

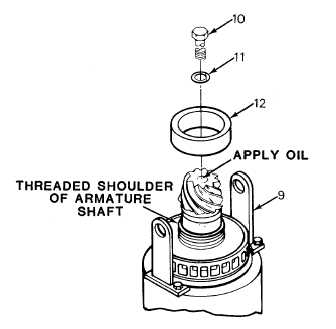

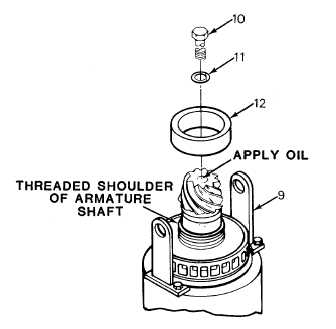

Remove bolt (10) and tab washer (11). Use a puller and remove oil slinger (

12) to expose armature shaft

threads.

4.

Check pinion bore for clean and smooth

condition. Fill chamber in armature and pinion

shaft to within 1 inch (25.4 mm) of top of pinion

bore with oil. Do not trap air while filling.

5.

Use the piston puller rod from disassembly tool

kit as a pump in the armature-shaft chamber

and purge chamber of air.

WARNING

To prevent the barrel from coming

loose, causing injury to personnel,

check that that it screws all the way

down on the armature shaft threads.

If unable to screw the barrel all the

way down, remove the barrel and

repair the damaged threads.

6.

Remove pull rod, leaving piston in place, and

screw the barrel of disassembly tool kit onto the

armature shaft.

7.

Screw cap assembly of disassembly tool kit into

the barrel until 1/8-inch (3 mm) clearance is left

between pinion and cap.

8.

Insert a 1-inch (25.4 mm) diameter bar in hole provided in bolt on cap of disassembly tool kit and steady the cap.

Position socket wrench on bolt.

3-235