winter use alcohol fed into air line by means of a cup.

Refer to paragraphs 105 through 107 for maintenance

instructions.

25. Viloco Bell Ringer Operating Valve

a. The valve is designed to control bell ringer

valve through inlet and is metered to bell ringer through

control port. Area through port is governed

Figure 2. Wick setting

d. How to Extinguish.

(1) Turn handwheel to left as far as it will go.

(2) When the flame has gone out raise the

drum by means of lifter handle M leaving

it in the raised position as shown in figure

prevents oil from creeping up on the

combustion tube which would cause an

odor when the burner is again lighted.

e. Care of Wicks and Burners. When the burners

are in long continuous use it is necessary, after ten or

twelve hours of steady burning, to turn the wick up and

down in order to loosen and break away any carbon at

the top of the wick tubes. Otherwise, this carbon will

seal the wick tightly at the top of the tubes and some of

the wick may be broken away, resulting in an

unsatisfactory flame. At least twice a week thoroughly

clean the brass wick tube. Refer to paragraphs 100

through 104 for maintenance instructions.

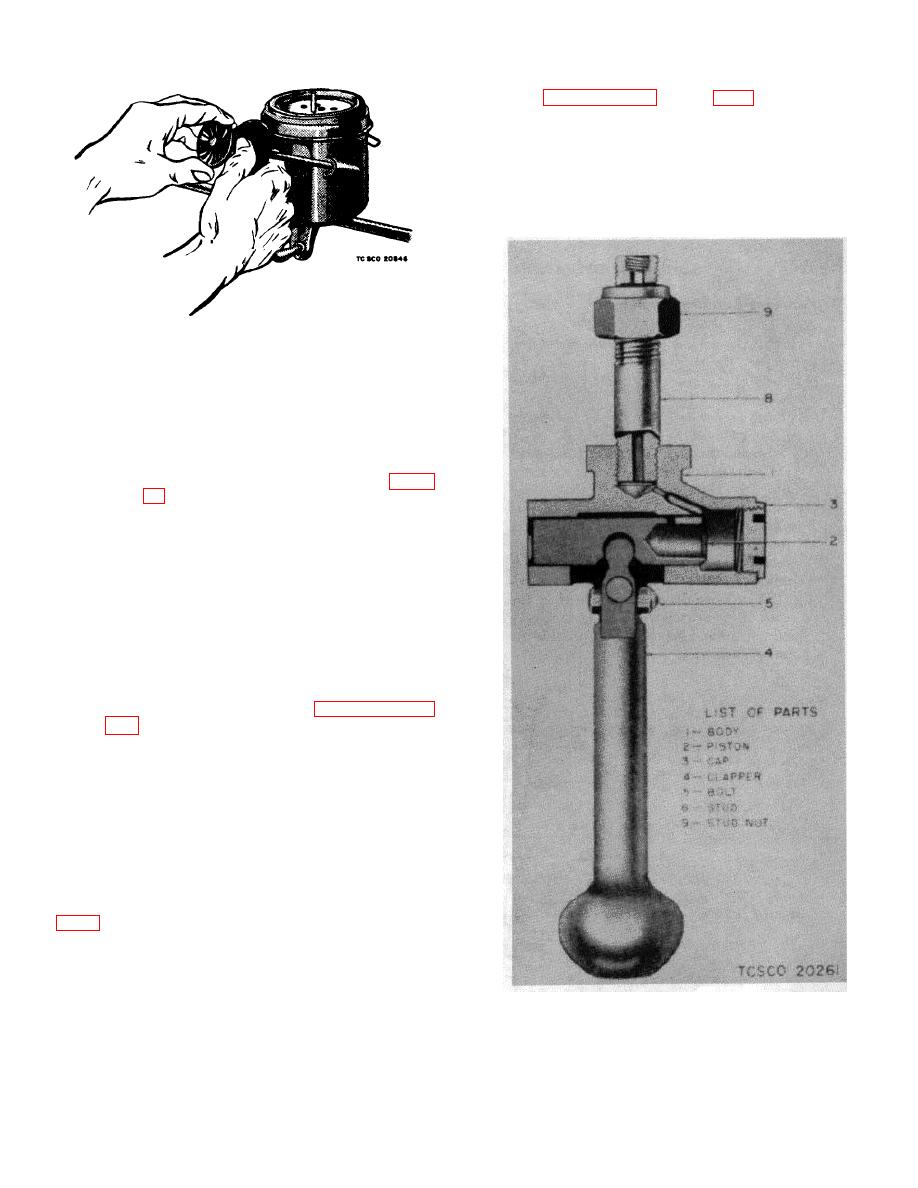

24. Viloco Internal Bell Ringer

a. Air from control valve enters through hole in

stud (8) and 1/16" orifice in body (1). Pressure moves

piston (2) swinging clapper (4) until exhaust port in

piston is uncovered. Since exhaust port has larger area

than inlet port, pressure in cylinder is instantly

exhausted and clapper rebounds moving piston in

reverse direction. Exhaust port is covered and air

pressure again builds up in cylinder for the next cycle

b. Should ringer fail to operate, it is generally

caused by dirt and gum adhering to piston or in cold

weather by moisture in air line freezing up inlet port.

Use a grade of light oil that will not gum up, and in

Figure 3. Internal bell ringer.

12